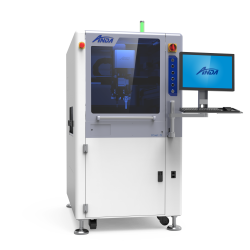

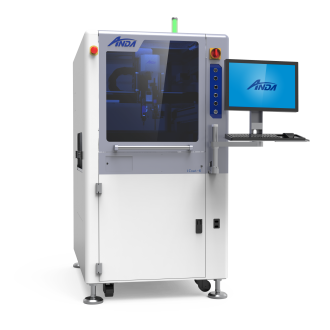

iCoat-6 Series

iCoat-6 High Precision Selective Conformal Coating Machine with Closed Loop Fluid Heating System

Features & Benefits

This highly precise, selective conformal coating machine offers closed loop fluid heating which provides a constant fluid viscosity, even in machine suspension.

The recirculating fluid delivery system offers stable fluid pressure and temperature, even under varying production and incoming air pressure conditions.

Standard Features

- Auto dipping and purging waste collection system

- Safety door lock system

- LED UV lamps for inspection

- ESD grounding point

- PCB clamping system

- Material level detection

- Material heating circulation system

- Material filtration system

- Low pressure fluid automatic adjustment system

- Film width laser checking system

- Diaphragm pump feeding system

- CE certifi ed

Optional Features

- CCD vision camera

- Barcode or 2D code scanning system

- UPS and voltage stabilizer

- Pallet return conveyor

- Programmable valve cleaner

- Track enhancement

- Material tank : 1 gal / 3 gal / 5 gal / 10 gal

System Specifcations

| Board Handling | |

| Standard Work Area |

X 360 x Y 450 x Z 850 mm (X 14.71" x Y 17.71" x Z 3.34") |

| Maximum Components Height | ± 90 mm (± 3.54") from PCB |

| PCB Edge Clearance | ≥ 5mm (≥ 0.19") |

| Single Spray Width | 2 – 30 mm (0.078" – 1.18") |

| Maximum Conveyor Width | 460 mm (18.11") |

| Minimum Conveyor Width | 50 mm (1.95") |

| Transmission System | |

| Process Flow |

L to R (Standard), R to L (Optional) |

| Conveyor Height | 900 ± 20 mm (35.43" ± 0.79") |

| Conveyor Speed (XY) | 2 - 13 m/min |

| Conveyor Width Adjustment | Automatic (motorized) |

| Operation Configuration | |

| Numbers of Valves |

Dual valves configuration with fixed valves separation |

| Maximum Speed | 800 mm/s |

| Repeatability | ± 0.02 mm (± 0.0007") |

| Facility | |

| Standard Footprint |

L 900 mm x W 1300 mm x H 1675 mm (L 35.43" x W 51.18" x H 65.94") |

| Weight | 560 kg |

| Motor Power | DC 24 V 69 W × 2 |

| Air Sources | 0.4 Mpa |

| Exhaust Requirement | 15 m³/min |

| Input Power | AC 220 V 50/60 Hz |

| Total Power | 2.4 KW |

| Interface | |

| Controller |

IPC and motion control card |

| Software | Anda user interface software with Windows |

| Programming | Keyboard & mouse mode |

| Communications Protocol | SMEMA |

Products

Products